Introduction

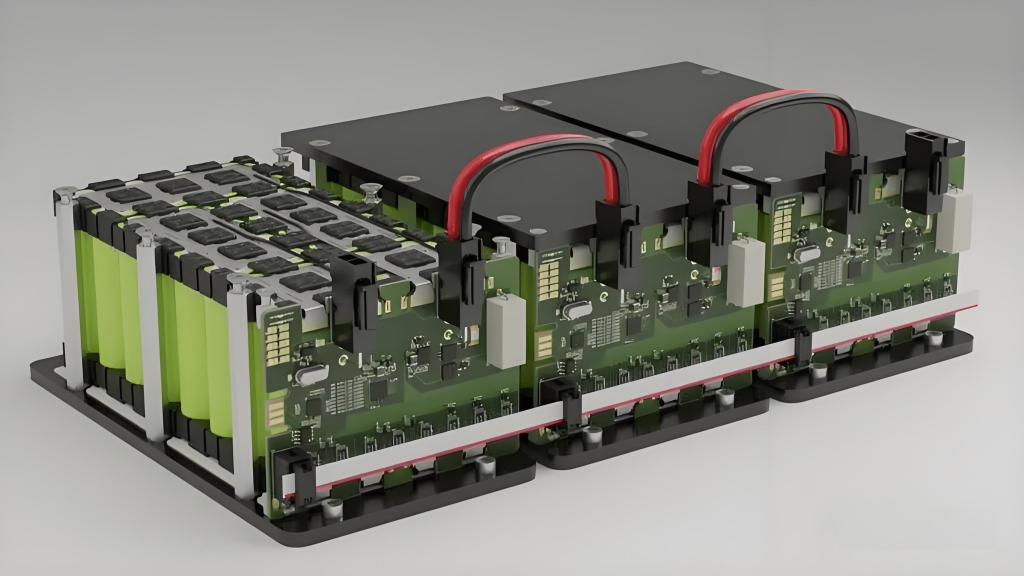

In the rapidly evolving world of electric vehicles and renewable energy storage systems, Battery Management Systems (BMS) play a pivotal role in ensuring the safety, efficiency, and longevity of batteries. At the heart of every BMS lies its PCBA (Printed Circuit Board Assembly), which serves as the backbone for monitoring, controlling, and protecting the battery pack. This comprehensive guide delves into the intricacies of BMS PCBA, exploring its functions, applications, design considerations, manufacturing nuances, and the global landscape of manufacturers.

1. Understanding BMS Products: Functions, Working Principles, and Components

BMS is a critical component in battery-powered systems, tasked with overseeing the health and performance of batteries. Its primary functions include:

- Monitoring: Continuously tracking battery parameters such as voltage, current, temperature, and state of charge (SoC).

- Balancing: Ensuring that all cells within a battery pack are evenly charged to prevent premature aging and failure.

- Protection: Implementing safeguards against overcharging, over-discharging, short circuits, and thermal runaway.

- Communication: Facilitating data exchange between the BMS and other system components, including the vehicle’s control unit.

BMS operates by leveraging a combination of sensors, microcontrollers, and power electronics. Sensors gather real-time data on battery conditions, while microcontrollers process this information and issue control commands to maintain optimal battery performance. Power electronics, such as MOSFETs and relays, are employed to execute these commands, enabling precise control over charging and discharging processes.

2. BMS Applications: A Focus on the Traction Battary Market

BMS finds widespread application across various industries, with a particular emphasis on the traction battary market. In the realm of electric vehicles, BMS is instrumental in managing large-scale battery packs, optimizing energy usage, and ensuring passenger safety. Similarly, in renewable energy storage systems, BMS optimizes the performance of batteries used to store solar or wind-generated electricity, enhancing grid stability and reducing energy waste.

3. Design Considerations for BMS PCBA

Designing an effective BMS PCBA necessitates a meticulous approach, encompassing several key considerations:

- Signal Integrity: Ensuring accurate and reliable data transmission across the board requires careful layout and routing of signal traces.

- Thermal Management: Efficient heat dissipation is crucial to prevent component overheating and maintain system stability.

- EMC/EMI Compliance: Minimizing electromagnetic interference (EMI) and ensuring electromagnetic compatibility (EMC) are essential for reliable operation in electrically noisy environments.

- Safety: Implementing robust protection mechanisms to guard against potential hazards, including overvoltage, overcurrent, and thermal runaway.

4. Leading BMS Electronic Manufacturers

The global BMS market is populated by several renowned manufacturers, each with its unique strengths and expertise. Some of the most prominent players include:

- Continental AG: A leading automotive supplier, Continental offers advanced BMS solutions tailored for electric and hybrid vehicles.

- LG Chem: As a major player in the battery industry, LG Chem provides comprehensive BMS solutions for a wide range of applications, including electric vehicles and energy storage systems.

- BYD Electronics: A Chinese multinational company specializing in renewable energy and electric vehicles, BYD’s BMS technology is renowned for its high efficiency and reliability.

- PCBONLINE : PCBONLINE specializes in battery management solutions, offering a range of BMS electronics manufacturing. Their BMS PCBA manufacturing is renowned for its reliability, performance, and advanced features.

It is worth noting that the industry landscape is constantly evolving, and besides these companies, there are other well-known manufacturers as well. When selecting a BMS PCBA manufacturer, one should consider factors such as product quality, industry reputation, certifications, technical support, and compatibility with specific battery system requirements. Conduct thorough research and evaluation to identify the most suitable manufacturer that meets your needs.

5. Manufacturing Challenges and Quality Control in BMS PCBA Production

Producing high-quality BMS PCBAs involves overcoming several challenges and implementing rigorous quality control measures:

- Material Selection: Choosing high-quality, temperature-resistant materials to ensure long-term reliability.

- Precision Assembly: Ensuring accurate and consistent component placement during the assembly process.

- Testing and Validation: Conducting thorough testing to verify the functionality, safety, and performance of the BMS PCBA.

- Environmental Testing: Exposing the PCBA to extreme conditions to assess its resilience and durability.

6. Evaluating BMS PCBA Suppliers: Key Competencies to Consider

When selecting a BMS PCBA supplier, it’s crucial to assess their comprehensive capabilities:

- Technical Expertise: A deep understanding of BMS technology and the ability to design and manufacture custom solutions.

- Quality Control: A robust quality management system to ensure consistent product quality and compliance with industry standards.

- Supply Chain Management: Efficient logistics and inventory management to minimize lead times and reduce costs.

- Customer Support: Responsive and knowledgeable customer service to address any issues or concerns promptly.

7. Advantages and Disadvantages of BMS PCBA Production in China

China, with its robust manufacturing infrastructure and skilled labor force, offers several advantages for BMS PCBA production:

- Cost-Effectiveness: Lower labor and production costs compared to other regions.

- Supply Chain Integration: Easy access to a vast network of suppliers and manufacturers.

- Technical Expertise: A growing pool of skilled engineers and technicians specialized in BMS technology.

However, there are also some potential drawbacks to consider, such as transportation costs, tariff issues, and the need for strict confidentiality controls to ensure intellectual property is protected. Therefore, choosing a manufacturer with a strong reputation and a well-established supply chain system is especially critical.

Conclusion

BMS PCBA is a vital component in the operation and safety of battery-powered systems, requiring meticulous design, precise manufacturing, and rigorous quality control. As the electric vehicle and renewable energy industries continue to expand, the demand for advanced BMS solutions will undoubtedly grow. By partnering with reputable manufacturers and suppliers, organizations can leverage the latest BMS technology to enhance the performance, reliability, and safety of their battery-powered products.