Flexible Die-Cut Circuits (FDCs), also known as Flexible Flat Cables, represent a key advancement in electronic circuit design and production. FDC technology diverges from traditional flexible printed circuit (FPC) manufacturing processes by employing Rotary Die Cutting Technology. This method carves circuit pathways into durable metal rollers, which precisely cut away excess copper, leaving only the essential circuit lines. After this, a protective layer is applied through heat lamination. In this article, we’ll delve into the production process, application domains, and advantages of FDCs, with an emphasis on their role in emerging technologies, particularly in electric vehicle battery systems.

1. Introduction to FDC Technology: Distinguishing FDC from FPC

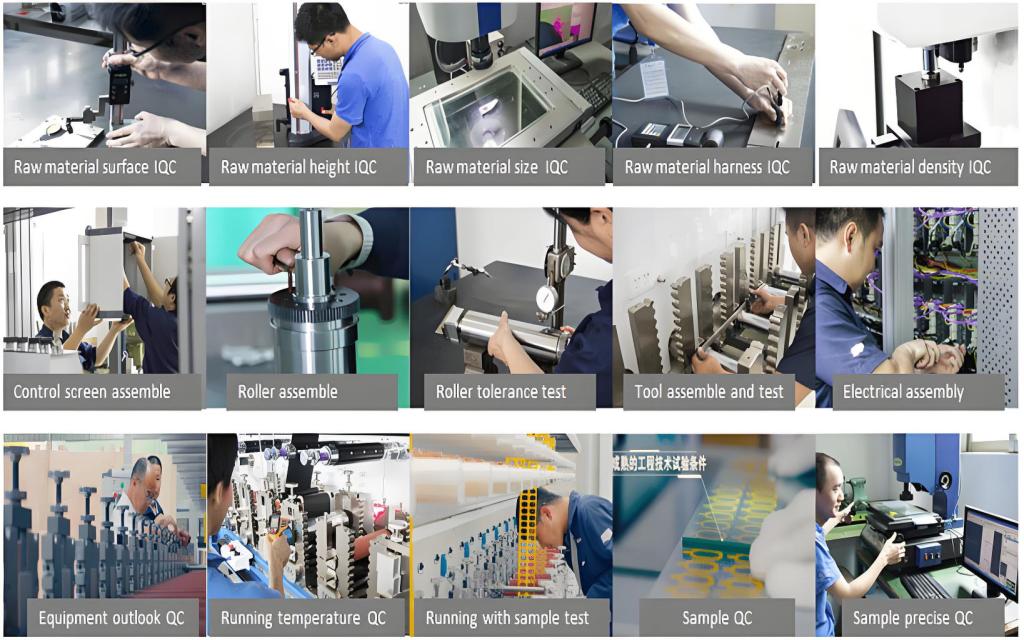

Image credit: PCBONLINE, showing their FDC connection technology.

The FDC differs fundamentally from FPC (Flexible Printed Circuits) in its approach to shaping circuitry on flexible materials. While FPCs are typically etched from copper-clad laminates, FDC technology leverages rotary die-cutting—a process where circuit patterns are pre-formed on metal rollers. Unlike traditional FPCs, which are constrained by complex chemical etching, FDC circuits are mechanically cut, improving consistency, precision, and scalability.

Where FPCs rely on subtractive etching methods, FDCs utilize automated rotary die-cutters. This setup enhances the process’s repeatability and enables high-volume production, making FDCs especially suited for applications where cost, precision, and durability are critical. FDCs also allow for continuous production, theoretically reaching unlimited lengths, while maintaining a controlled width of about 250 mm. The minimal line width and spacing achievable by FDC technology surpass traditional FPC capabilities, opening up new applications where these circuits provide higher resilience, especially in demanding environments like automotive and IoT applications.

2. How FDCs Are Produced

The production of FDCs follows a streamlined yet highly precise process that maximizes efficiency through automation:

- Substrate Selection: FDCs typically employ flexible substrates such as polyimide (PI) or polyester (PET) due to their durability and heat resistance.

- Rotary Die-Cutting: The core of the FDC production process lies in rotary die-cutting. Here, metal dies, which have pre-designed circuit pathways engraved on them, rotate and precisely cut the copper foil adhered to the substrate. This method allows for exact cuts, producing clean, defined edges while preserving the flexibility of the material. Unlike etching, die-cutting doesn’t involve chemicals, making it more environmentally friendly and less prone to dimensional inconsistencies.

- Layering and Lamination: Once the circuit pattern is created, protective laminates are applied to seal the circuit. This lamination can include adhesive layers, protective films, or shielding layers, depending on the end-use requirements.

- Technical Capabilities: FDC technology allows for line widths and spacing as narrow as several hundred micrometers, suitable for densely packed electronic applications. The rotary die-cut method supports continuous lengths and a controlled width range, with high tolerances, making it ideal for large-scale production with consistent quality.

- Multi-Layer Compatibility: Advanced rotary die-cut machines support multi-layer designs, allowing for complex FDC layouts and circuits that support higher functionality and integration, often necessary in applications like automotive sensor networks or long-distance communication modules.

3. Application Domains for FDCs

Flexible Die-Cut Circuits are gaining traction in various industries due to their unique features:

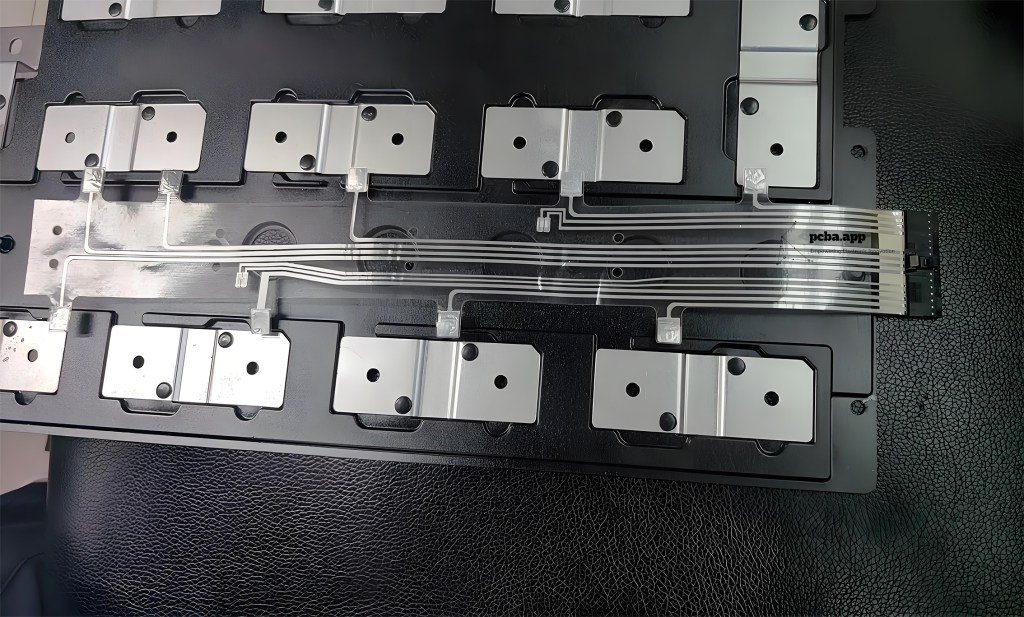

- Automotive Industry: FDCs are becoming crucial in electric vehicles (EVs), particularly in the battery pack CCS modules where cost-effectiveness, flexibility, and reduced reliance on nickel tab welding are essential. FDCs streamline the connection process by integrating complex circuits into a single flexible assembly, ideal for the compact and tightly-packed environments of EV battery modules.

- Long-Range Sensing and IoT: FDCs have applications in long-range inductive sensing and IoT sensors, thanks to their flexibility and high durability. For instance, FDCs are used in IoT sensors that require high sensitivity and resilience under repetitive motion, providing stable data transmission in compact, flexible designs.

- Medical Equipment and Wearables: The biocompatibility and flexibility of FDCs make them suitable for wearable health monitors and medical devices, where they provide accurate data transmission while conforming to the body’s contours, enhancing user comfort.

- Consumer Electronics: FDCs contribute to ultra-thin designs in smartphones, tablets, and wearables, where they facilitate compact and lightweight connections between circuit components without compromising on durability or performance.

4. Advantages of FDCs in Electric Vehicle Battery Packs

In the realm of EV battery pack construction, FDCs present several unique advantages over traditional circuit technologies.

Image credit: PCBONLINE, showing their FDC connection technology.

- Reduced Cost and Assembly Time: FDCs eliminate the need for nickel tabs, commonly used in battery connections, thereby reducing the complexity and cost of assembly. With rotary die-cutting, FDCs enable a more straightforward battery design by integrating circuits into a single, flexible layer that can cover large areas without additional components or soldering requirements.

- Enhanced Reliability and Durability: The flexible nature of FDCs minimizes the risk of damage from vibrations and thermal expansion, both of which are common in automotive applications. Unlike rigid PCBs, FDCs conform to the battery pack’s contours, allowing for efficient use of space while ensuring reliable electrical connections.

- Improved Thermal Management: FDCs support efficient heat dissipation in tightly packed battery modules. The integration of copper foil and insulating layers allows for effective thermal transfer, reducing the risk of overheating and extending battery life.

- Customization and Modularity: FDCs offer design flexibility, allowing manufacturers to create custom layouts that fit precisely within the EV battery pack’s geometry. Rotary die-cutting also enables manufacturers to produce modular components, simplifying maintenance and upgrades without redesigning the entire pack structure.

- Scalability for Mass Production: With FDC technology, EV manufacturers can achieve high-volume production while maintaining quality consistency. The automated rotary die-cut process allows for rapid scalability, meeting the growing demand for EV battery packs without significant increases in production costs.

5. Leading Global FDC Manufacturers

Several companies lead in the development and production of FDC technology, combining advanced manufacturing capabilities with innovative circuit designs:

- Molex: Known for its expertise in flexible electronics, Molex provides customized FDC solutions for automotive, medical, and consumer electronics industries.

- 3M: As a pioneer in adhesive and flexible material technologies, 3M integrates FDC production with advanced material science, serving applications in both industrial and consumer markets.

- TE Connectivity: Specializing in high-performance electronics, TE Connectivity produces FDCs for critical applications, including aerospace and automotive sectors, where durability and precision are paramount.

- Sumitomo Electric: With a focus on automotive and energy applications, Sumitomo produces FDCs with specialized materials that withstand extreme conditions, catering to sectors like electric vehicles and renewable energy systems.

- Amphenol: A key player in connector and interconnect systems, Amphenol offers FDCs with multi-layer designs suitable for high-performance electronic systems across multiple industries.

- PCBONLINE: PCBONLINE has focused on new energy battery management solutions for over a decade, offering a comprehensive range of electronic manufacturing services, including CCS (Cell Contact System), BMS (Battery Management System), and high-power inverters. Leveraging a strong supply chain in China and integrated sourcing capabilities for CCS orders, PCBONLINE has become renowned for reliability, stable performance, and professional service in FDC design and production.

6. Advantages of FDC Compared to FPC

FDC (Flexible Die-Cut Circuit) technology offers several key advantages over traditional Flexible Printed Circuits (FPC):

- Simplified Process and Reduced Costs

FDC production requires fewer steps—typically around 10 compared to over 20 in FPC processes. This reduction minimizes labor, materials, and energy costs, leading to a lower overall product cost. - Environmental Benefits

Unlike FPC manufacturing, which involves chemical etching and extensive cleaning processes that generate wastewater, FDC uses a die-cutting method that requires fewer chemicals and produces close to zero pollution. This makes FDC a more environmentally friendly option. - Efficiency and Production Speed

FDC processes are inherently faster due to their simplified steps. The streamlined manufacturing increases throughput and shortens lead times, making it an ideal choice for high-demand applications. - Design Flexibility for Specific Applications

FDC is particularly suitable for applications requiring precise, consistent cuts, as seen in battery management systems and sensor integration. This is especially useful in sectors like electric vehicles and IoT, where design complexity and high reliability are critical.

These advantages make FDC a competitive alternative to FPC for specific applications that benefit from efficiency, cost-effectiveness, and environmental sustainability.

7. Conclusion

Flexible Die-Cut Circuits (FDCs) represent a significant advancement in circuit technology, offering unique benefits in terms of cost-efficiency, scalability, and durability. Through the use of Rotary Die Cutting Technology, FDCs achieve a high degree of precision and reliability, making them an ideal choice for applications requiring both flexibility and resilience. Their adoption in EV battery packs and IoT sensor modules highlights their potential in rapidly growing markets, while ongoing advancements in die-cutting technology promise even greater possibilities for the future. As FDC technology continues to evolve, it is set to redefine standards in flexible electronics, enabling innovations across various fields and contributing to the broader adoption of sustainable and efficient electronic solutions.